Custom Design

If you are interested in designing your own engagement ring or other jewelry, contact our Master Jeweler below if you would like to start the process!

The Custom Jewelery Journey:

Design Meeting

It all starts with a meeting in our state of the art design room. We will discuss options to accomodate your personalized design and the process of making it a reality.

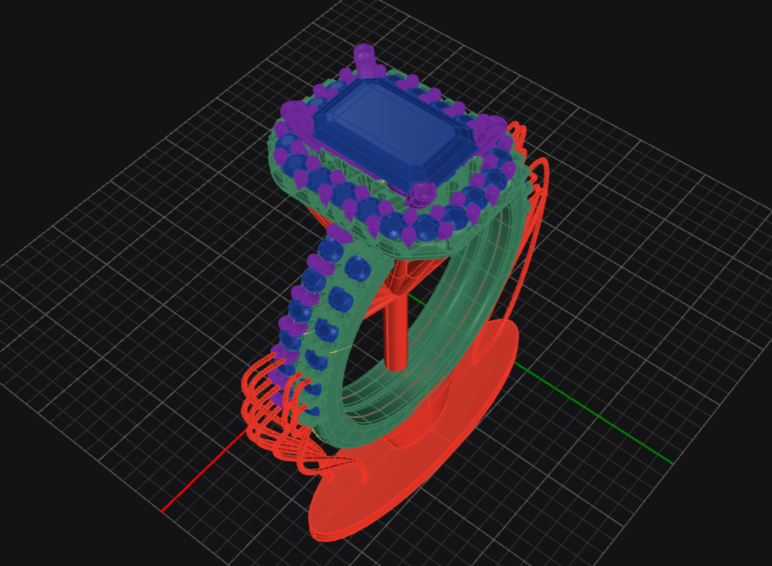

3D CAD Drawing

We take your ideas and use our advanced CAD software to create a collage of renderings which will be sent to you for approval.

Rendering

What is a rendering? Our CAD software creates a realistic image of your design. Pending your approval, we move on with the process.

3D Printed Model

Once the rendering is approved and the deposit is made, the design is loaded into our 3D printer where a resin model is created which is used for casting. This is a great time to come into the store to inspect the piece for any final changes.

Casting

The 3D model is now ready to begin the casting process in which the model is burned out at 1,500 degrees Farenheit over a duration of 12 hours. This is where we take your choice of metal from liquid to design.

Stone Setting

At this point in the process, the seats are cut by our Master Jeweler and the stones are set.

The Final Product

The final finish is applied, the peice is thoroughly cleaned, inpsected, and evaluated for an appraisal.